Telco networks are transforming at the edge, driving unprecedented complexity in fiber operations. As 5G densification accelerates and FTTH penetration exceeds 60% in developed markets, regional telco edge automation has become mission-critical. Regional cabinets and remote long-haul CO management sites now handle live routing, grooming, and restoration functions that once required central office resources. Manual patching fails catastrophically in these environments — especially outdoors, where temperatures swing from −40 °C to +65 °C and a single truck roll costs $800-1,200.

OSP robotic switch technology delivers the automation breakthrough operators need: eliminate 200+ annual field dispatches, achieve sub-minute service restoration, and maintain −70 dB crosstalk performance in the harshest environments. This comprehensive guide explains how automated OSP switching strengthens network resilience, reduces OPEX by 35-45%, and prepares operators for the next decade of fiber expansion.

Edge sites are multiplying exponentially. Street cabinets, mini-COs, and regional handoff points now manage FTTH distribution, 5G midhaul transport, wholesale interconnect, and rural backhaul. According to industry forecasts from Dell’Oro Group, edge fiber termination points are expected to nearly triple by 2027 — yet these locations remain one of the least automated segments of the network.

Outdoor cabinets face brutal conditions that manual patch panels cannot withstand. Temperature swings from −40 °C to +65 °C cause connector expansion/contraction, while dust infiltration degrades optical performance by 2-3 dB annually. XENOptics' CSOS platform, engineered specifically as an OSP robotic switch for these conditions, includes:

Regional nodes now terminate 2,000-5,000 live strands, up from 200-500 just five years ago. Meanwhile, skilled fiber technicians are retiring faster than replacements enter the workforce. The Fiber Broadband Association reports a 12,000-technician shortage that will double by 2026.

Remote long-haul CO management through robotic switching addresses this crisis by:

Modern SLAs demand 99.999% availability with <4-hour MTTR. Missing these targets triggers penalties averaging $50,000/month for regional transport providers. One Tier-2 carrier documented $2.3M in annual SLA penalties directly attributable to manual patching delays at edge sites.

OSP robotic switch deployments eliminate these penalties through:

Traditional patch panels experience 15-20% annual failure rates in these conditions, driving emergency truck rolls that cost $1,500-2,000 each.

Modern OSP automation transcends motorized patch panels. True regional telco edge automation requires temperature-hardened robotics, military-grade environmental protection, and carrier-grade optical performance.

Core Architecture: The CSOS/XSOS PlatformThe XENOptics CSOS family demonstrates reference architecture for OSP robotic switch implementations:

| Component | Specification | Industry Standard | Performance Advantage |

|---|---|---|---|

| Operating Range | −40 °C to +65 °C | −20 °C to +50 °C | 45% wider range |

| Humidity Tolerance | 5-95% non-condensing | 10-85% | Tropical deployment ready |

Achieving carrier-grade performance in OSP environments requires exceptional optical specifications:

| Parameter | CSOS Performance | Industry Typical | Impact on Network |

|---|---|---|---|

| Insertion Loss | ≤1.0 dB | 1.5-2.0 dB | 33% better power budget |

| Return Loss | < -55 dB (UPC) | < -45 dB | Superior reflection control |

| Crosstalk | −70 dB | −60 dB | 10x better isolation |

| PDL | 0.15 dB | 0.25-0.30 dB | 40% polarization improvement |

Critical for remote long-haul CO management: established connections remain intact during power failures. The passive latching mechanism ensures:

OSP sites often rely on solar/battery power, making efficiency crucial:

| State | Power Draw | Duration | Daily Energy |

|---|---|---|---|

| Switching | 36-60W | 45 seconds/switch | <1 Wh |

| Idle | 6W | 23+ hours | 140 Wh |

| Deep Sleep | <0.5W | Configurable | 12 Wh |

Challenge: Supporting 12 remote aggregation sites in harsh terrain with −40 °C to +65 °C temperature swings and multi-hour drive times.

Solution: Installed 12 CSOS-144 OSP robotic switches, each replacing a manual patch panel and connecting back to a central NOC.

Results (12 months):

Challenge: Operating 18 regional fiber huts across long mountain roads, where manual fiber work often required half-day dispatches.

Solution: Deployed 18 CSOS-144 OSP units, centralised under one management platform.

Results (first year):

Challenge: Managing fiber backhaul for 2,300 small cells with stringent latency requirements and tropical conditions (95% humidity).

Solution: Deployed CSOS-144D OSP (Compact Smart Optical Switch) units with environmental sensors and predictive analytics.

Measured Benefits:

Deploying OSP robotic switches in carrier networks requires extensive compliance verification:

| Standard | Requirement | CSOS Compliance | Verification Method |

|---|---|---|---|

| ETSI 300019 | Class 3.2 outdoor unprotected | Exceeds | 24-month field trial |

| IEC 61300-2-19 | Damp heat cycling | Passed 2000 hours | Accelerated aging test |

| Telcordia GR-326 | Connector reliability | >10,000 cycles | Automated endurance test |

The convergence of 5G and edge computing requires unprecedented flexibility in fiber connectivity. MEC hub integration with robotic switching enables dynamic routing of traffic between cell sites and distributed compute resources, supporting latency-sensitive applications like autonomous vehicles and augmented reality.

Evaluate existing infrastructure for OSP robotic switch compatibility:

Develop deployment architecture for regional telco edge automation:

Install initial OSP robotic switches at 2-3 representative sites:

Scale deployment across all regional sites:

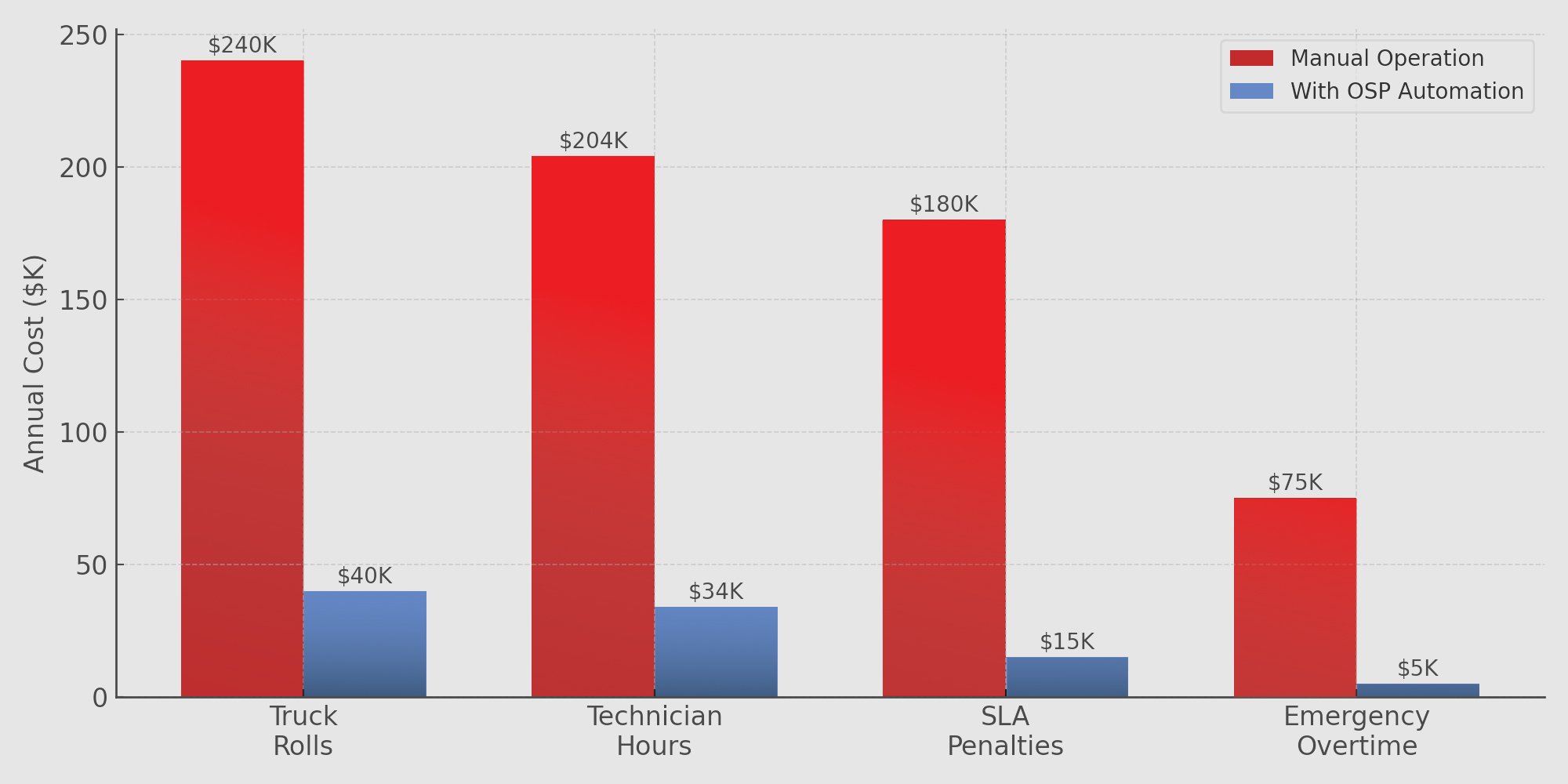

| Cost Category | Manual Operation | With OSP Robotic Switch | Annual Savings |

|---|---|---|---|

| Truck Rolls | 240 × $1,000 | 40 × $1,000 | $200,000 |

| Technician Hours | 2,400 × $85 | 400 × $85 | $170,000 |

| SLA Penalties | $180,000 | $15,000 | $165,000 |

| Emergency Overtime | $75,000 | $5,000 | $70,000 |

| Total Direct | $695,000 | $94,000 | $601,000 |

Regional telco edge automation enables next-generation services:

The OSP robotic switch roadmap includes:

Remote long-haul CO management through OSP robotic switches represents a fundamental shift in network operations. Organizations achieving the greatest success follow this proven approach:

The regional telco edge demands automation that can withstand brutal outdoor conditions while delivering carrier-grade performance and software-speed operations. XENOptics CSOS makes this possible today.

Join leading operators worldwide who have eliminated many annual truck rolls per region, achieved sub-minute service restoration, and reduced edge OPEX by 35-45% with robotic OSP fiber management.

© 2018-2026 XENOptics. All Rights Reserved. Terms of Use.