XSOS and CSOS give network teams a robotic, non-blocking fiber fabric that you can reconfigure from the NOC—no truck rolls, no manual patching, and no service impact during field work. The platform’s passive-latching design maintains light paths during power events and module swaps, so planned maintenance and surprise outages don’t become customer incidents. Field-replaceable modules are standard, and switching tasks complete within tens of seconds, not minutes or hours. CSOS brings the same capabilities to compact, edge, and unmanned sites—ideal for street cabinets, remote huts, and small POPs.

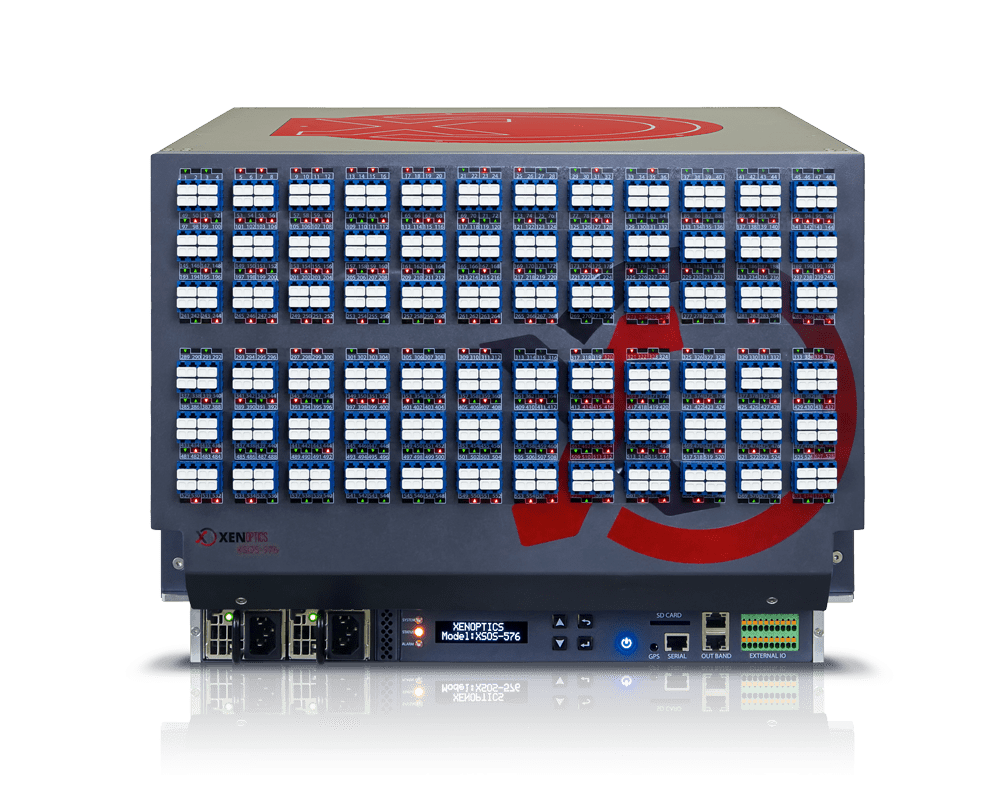

XSOS scales with your footprint: the XSOS-288 supports a 144×144 matrix (up to 1,728 ports per rack side, or 3,456 using dual sides), while the XSOS-576D doubles fabric capacity to 576 ports and can approach 7,000 managed ports using a back-to-back rack layout. Both fit standard 19-inch racks and deliver carrier-class optics with connectorized configurations, enabling straightforward deployment in central offices, metro POPs, and hostile OSP enclosures. For space- and power-constrained locations, CSOS (e.g., 72S/144D variants) delivers the same automated cross-connect workflows in a shorter-depth chassis, hardened for outside-plant conditions.

Critically for Zero Touch & Zero Trust operations, XSOS and CSOS expose secure, open interfaces for orchestration (Web GUI, SNMP, RESTful API) and centralized control via the XENOptics NMS with role-based authentication and full audit logs—so you enforce consistent policy from the core to the edge.

Replace manual ODF workflows with robotic cross-connects to accelerate turn-ups, reroutes, and maintenance windows. XSOS provides a non-blocking matrix and passive latching that keeps established connections active even as modules are swapped or power is interrupted. That stability makes it a strong foundation for APS designs at Layer 1—your controller can pre-provision standby paths and command XSOS to swing ports during fiber-level failures.

XSOS-288 and XSOS-576D deliver high-density fiber management with typical connectorized insertion loss of ≤ 0.8 dB (XSOS-288) or ≤ 1.0 dB (XSOS-576D) and return loss ≥ 55 dB with UPC connectors—numbers that reflect real-world field deployments. Switching actions complete in roughly 35–60 seconds (XSOS) and 24–40 seconds on compact CSOS systems.

The XENOptics NMS provides topological views, connection/disconnection workflows with queued tasks, live camera streams during operations, customer/tenant portals (when applicable), user management, and detailed logs—all accessible via web and REST/SNMP. This turns “patching” into a deterministic, trackable workflow that integrates cleanly with SDN controllers and OSS/BSS.

5G radios, fronthaul/midhaul/backhaul nodes, and street-level cabinets demand OSP-ready gear. CSOS compact units extend XSOS automation into space- and power-constrained locations, supporting ruggedized deployment down to –40 °C and up to +65 °C (street-cabinet range) with the same passive-latching continuity.

That means fewer dispatches, faster restores, and consistent optics from the cell edge to the core.

For FTTx/PON and MDU/FTTB distribution, robotic fiber automation eliminates manual re-patching when migrating ONTs, rebalancing splitters, or changing service providers.

Where operators adopt open-access models, automated cross-connects and NMS workflows make tenant turn-ups and provider swaps predictable—in seconds, not site visits. (MSOS materials illustrate the operational model for multi-dwelling deployments.)

XSOS focuses on remote fiber management. For diagnostics (OTDR/RFTS), pair the platform with third-party test solutions via your management stack; NMS surfaces state, queues actions, and logs changes so you can correlate optical tests with physical reconfigurations.

This separation of duties preserves operational clarity and security.

Automating cross-connects in submarine landing stations and meet-me rooms (MMRs) removes human variables and reduces mean time to restore (MTTR) after fiber cuts or amplifier issues.

XSOS maintains power-independent traffic through passive latching; an internal super-capacitor safely completes in-flight state changes during power loss.

XSOS platforms are engineered and qualified against telco-grade environmental and safety baselines, including NEBS 3/GR-63-CORE and ETSI 300019 Class 3.2.

Operating ranges cover controlled room deployments and OSP enclosures (–40 °C to +65 °C for street-cabinet CSOS). For temperature cycling, reference IEC 60068-2-14:2023, Test Nb—an appropriate citation for environmental qualification language.

NMS supports centralized auth (including RADIUS/TACACS+/LDAP), granular roles, and comprehensive audit trails.

Combined with a strict posture that withholds interactive shell access (Telnet/SSH) from customers, XSOS aligns with Zero-Trust production environments without slowing change control.

| Model | Max Ports / Fabric | Typical Insertion Loss (dB) | Switching Time (s) | Operating Temp (typ.) |

|---|---|---|---|---|

| CSOS-72S / CSOS-144D | 72 (simplex) / 144 (duplex) | ≤ 1.0 | 24–40 | –5 °C to +45 °C (–40 °C to +65 °C in street cabinets) |

| XSOS-288 | 144×144 (up to 1,728 ports per rack side) | ≤ 0.8 | 35–60 | –5 °C to +45 °C (OSP options) |

| XSOS-576D | 576 (near-3,500 per side; ~7,000 back-to-back) | ≤ 1.0 | 35–60 | –5 °C to +45 °C (OSP options) |

Notes: (1) Values reflect connectorized systems—XENOptics’ standard field configuration.

As next-generation broadband and mobile networks rapidly expand, operators face unprecedented demand to deliver higher bandwidth and ultra-reliable connectivity.

Continue Reading →

Subsea capacity only moves at the speed of the shore end. If circuit turn-ups at your cable landing station (CLS) still rely on manual patching and scarce maintenance windows, you’re leaving bandwidth—and money—at the waterline.

Continue Reading →

Satellite ground stations face pressure to run with minimal staff, driven by cost, uptime, and harsh environments. Manual RF patching in ODFs or coax matrices risks downtime and errors.

Continue Reading →

Turn outages into minute-long blips—and slash OPEX while you’re at it. MSOS pairs integrated OTDR testing with robotic switching at the physical fiber layer.

Continue Reading →

Modern telecom networks evolve on central‑office time: now. As FTTx footprints and 5G xHaul scale, COs must manage thousands of optical terminations without sending technicians into crowded ODFs.

Continue Reading →

As telecommunications networks evolve to support 5G densification and FTTx expansion, manual fiber management has become a critical bottleneck.

Continue Reading →

© 2018-2026 XENOptics. All Rights Reserved. Terms of Use.