Your fiber layer doesn’t need to sip power all day. Passive-latching optics use energy only while switching, then sit at ~6 W in standby—often reclaiming ~85–90% of “always-on” draw versus motorized cross-connects that hold power to maintain paths (assume ~50 W; validate on site). Result: lower OPEX, steadier SLAs, and zero-touch fiber provisioning from the NOC.

“6 W idle vs. 50 W continuous saves ~385 kWh per frame each year.”

*Assumes 50 W legacy standby. Validate against your installed baseline.

Think of it like a light switch that stays in position without power. The actuator moves once to make the connection, then locks in place—no electricity needed to maintain the path. If utility power blips mid-change, an onboard super-capacitor UPS completes the action, and latched circuits keep passing light.

Impact: up to ~85–90% reduction in fiber-layer power versus keep-alive motors (baseline dependent).

Per frame (illustrative): If your current units idle at ~50 W and passive-latching idles at ~6 W, the delta is 44 W.

Annual saving = 44 W × 8,760 h ≈ 385 kWh per frame.

Example roll-ups

Quote: “385 kWh/frame/year adds up fast across MMRs and MDFs.”

Notes: 50 W legacy standby is an assumption—measure your installed base to refine.

Provision, move, and rollback from software—no truck rolls, no manual patching windows.

Outcome: zero truck rolls for routine changes; predictable change windows; clean audit trails. See a live topology & queue demo.

SLA stability starts with realistic optics. In connectorized deployments (standard), publish IL < 1.0 dB and RL ≥ 55 dB (UPC)—field numbers that keep budgets honest.

Impact: SLAs maintained through power events; fewer 3 AM escalations.

Mini-scenario: A power event hits at 02:07. With motorized holders, every active connection wants energy to stay put—risking drops. With passive-latching, paths remain locked; your NOC sees a completed task, not a cascade.

Scale fiber like software, not construction.

Result: more capacity, less fiber chaos, no re-wire projects.

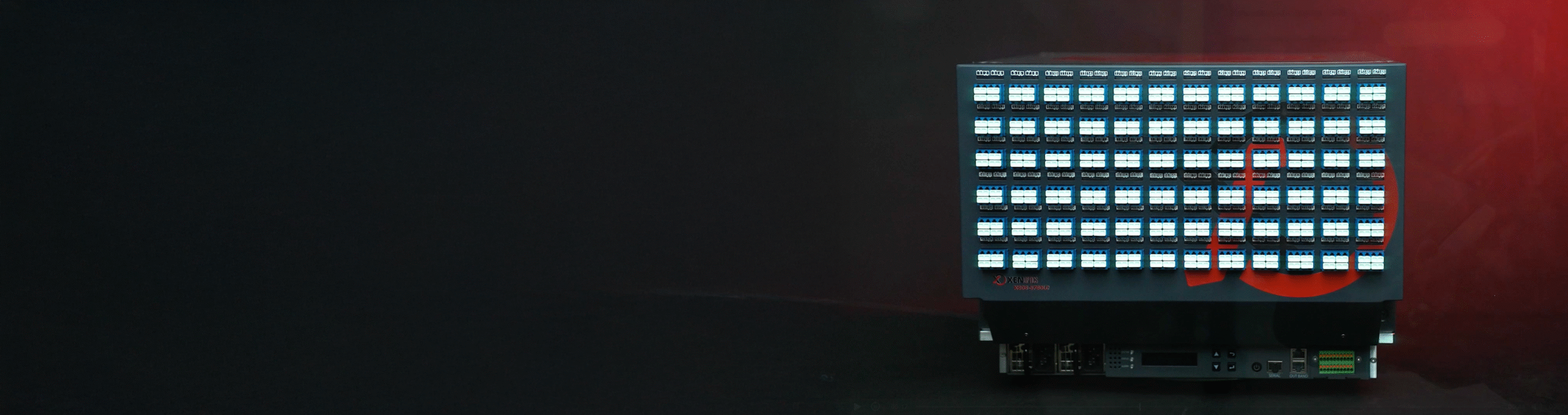

Micro-CTA: Map your MMR/MDF to 288/576 footprints → (layout options available).

| Metric | Traditional Motorized* | Passive-Latching | Savings |

|---|---|---|---|

| Standby power | ~50 W* | ~6 W | ~88% |

| Annual kWh / frame | ~438* | ~53 | ~385 |

| Power needed during outage to hold paths | Required* | None | 100% |

*Assumptions for legacy gear. Validate your installed baseline before final ROI.

Takeaway: reclaim most “always-on” fiber power while improving change control.

We’ll model your MMR/MDF inventory, measure idle power of current frames, and produce a line-item energy+labor ROI. Then we’ll map a phased migration to 288/576 latching fabrics in standard racks. Book a 30-minute savings assessment & remote online demonstration of the XSOS switches and Network Management System.

© 2018-2026 XENOptics. All Rights Reserved. Terms of Use.