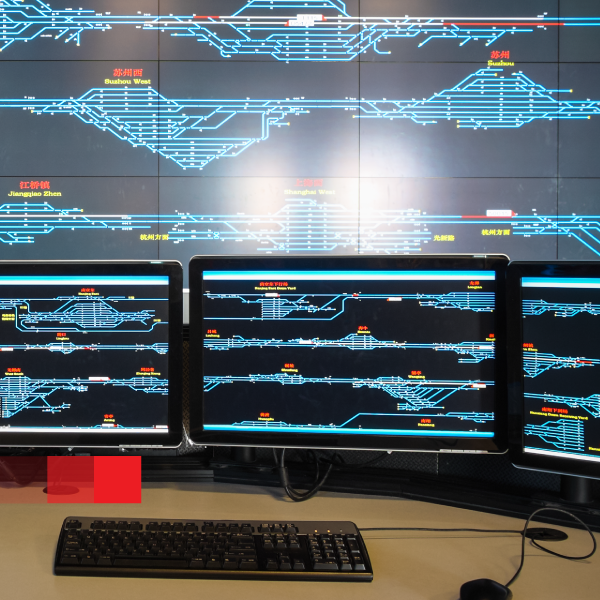

Railway fiber backbone automation is now a foundational requirement for modern rail and metro networks. Signaling, CCTV, passenger information systems, traction substations, SCADA, and emergency communications all depend on optical paths that must remain correct, auditable, and resilient under operational stress.

Across Europe and Asia-Pacific, metro operators now manage fiber corridors exceeding 50–120 km, with hundreds of unmanned endpoints distributed across stations, tunnels, and wayside cabinets. In this environment, manual fiber operations no longer scale. Dispatch delays, access restrictions, and documentation gaps directly impact service availability and safety-critical systems.

As rail networks integrate into Smart Cities programs, operators are adopting automated fiber switching to bring physical-layer connectivity under remote, governed control. Instead of dispatching technicians to move patch cords, rail teams can now reconfigure physical light paths from the OCC—without interrupting live services and with a complete audit trail aligned to railway RAMS methodology (EN 50126).

| Capability | Operational Value | Standards Alignment |

|---|---|---|

| Remote physical cross-connects | Eliminates dispatch delays to restricted rail locations | EN 50126 (RAMS), IEC 62280 |

| OCC-to-corridor deployment | Consistent control from core to OSP cabinets | EN 50159 |

| Passive latching during outages | Maintains live circuits during power loss | EN 50155 |

| Task-queue automation | Deterministic, auditable change control | EN 50126 change governance |

| Low-power cabinet operation | Extended autonomy for trackside cabinets | EN 50155 power requirements |

Rail and metro fiber networks differ fundamentally from enterprise environments. They are linear, geographically exposed, and tightly coupled to operational safety.

Operators must manage three environments simultaneously:

In a typical metro deployment, a single corridor may include 150–300 fiber termination points, many accessible only during short possession windows. Under these conditions, railway fiber backbone automation is not an optimization—it is an operational necessity.

A metro optical-network switch enables deterministic control of physical fiber paths, allowing Layer 0 behavior to be governed with the same rigor already applied to signaling and communications systems.

Defense deployments are not climate‑controlled labs. They are street cabinets, pad‑mounted shelters, trailers, ship racks, and exposed sites.

The compact CSOS line is explicitly designed for harsh Outside Plant environments:

XSOS systems share the same environmental philosophy and support deployment in street cabinets and harsh edge locations under ETSI 300019 Class 3.2 and NEBS 3 environmental standards.

Mechanically, both families are built for long service in tough conditions:

The platforms are engineered for a 20‑year service life, matching the lifecycle of fiber infrastructure rather than short server refresh cycles.

Manual fiber patching introduces measurable delay and risk in rail environments.

In one documented metro incident in 2024, a fiber fault inside a tunnel section required:

Even when executed correctly, manual fiber changes slow response. When mistakes occur, mean time to recovery (MTTR) routinely exceeds 40–60 minutes, well outside the service restoration targets defined in EN 50126-aligned operational plans.

Automated fiber switching replaces ad-hoc physical intervention with controlled execution, allowing rail teams to restore or reroute paths remotely—typically in under 3–5 minutes end-to-end, including approval and audit logging.

Automated fiber switching uses robotics to execute physical fiber cross-connects under software control. It transforms the physical layer from a static asset into a governed control surface.

It provides:

It does not inspect packets, analyze traffic, or replace diagnostic tools. Its role is explicit: controlled physical-layer reconfiguration, aligned with railway operational and safety frameworks.

In practice, rail operators deploy this capability using high-density indoor systems (such as XSOS-class platforms) and compact ruggedized systems for corridor and OSP cabinet deployment (such as CSOS-class platforms), while maintaining a unified operational model.

Rail deployments apply automated fiber switching where it removes the most operational friction.

At OCCs and network hubs, automated switching replaces manual optical distribution frames. This enables:

In these environments, a metro optical-network switch supports hundreds to thousands of managed ports with full auditability—critical for EN 50126 compliance.

Stations and depots experience frequent change driven by rolling stock upgrades, new passenger systems, and radio deployments. Automated fiber switching allows operators to pre-terminate fiber once and reassign paths remotely.

Along the corridor, OSP cabinet deployment introduces stricter constraints. Trackside cabinets often operate on battery-backed power and must remain stable during outages. Compact automated switching systems are designed specifically for these conditions.

Railway electronic equipment must tolerate power interruptions without introducing unsafe states. Passive latching during outages directly supports this requirement.

A passively latched optical connection remains physically connected without continuous power. Energy is consumed only when a connection changes state. Once latched, the fiber path remains intact even if cabinet power is lost entirely.

This behavior aligns with EN 50155, which mandates defined behavior during power interruptions and controlled degradation during extended outages. For rail operators, passive latching is therefore a compliance-driven design requirement—not a convenience.

Rail networks prioritize predictability over raw speed. Automated fiber switching platforms used in rail environments typically complete physical cross-connect operations in 36–60 seconds, depending on port distance and task queue depth.

This performance is sufficient to:

Power behavior reinforces resilience, particularly in remote locations. Low idle consumption and deep-sleep behavior—including <0.5 W sleep mode in some cabinet deployments—extend operational autonomy during prolonged outages.

Automation must respect railway change governance. Task-queue automation ensures physical-layer changes execute safely and predictably.

A standard workflow includes:

This model directly supports EN 50126 RAMS processes and reduces human error at Layer 0.

Rail infrastructure increasingly overlaps with municipal and utility networks. Stations host city systems. Corridors carry shared conduits. Emergency services depend on rail connectivity.

Within Smart Cities initiatives, utility-network fiber management requires predictable, auditable physical-layer behavior across stakeholders. Automated fiber switching enables rail operators to participate in shared infrastructure models while retaining operational control and compliance responsibility.

Rail and metro networks are no longer static utilities. They are dynamic, safety-critical digital platforms embedded within Smart Cities.

By combining railway fiber backbone automation with controlled OSP cabinet deployment, passive latching during outages, and task-queue automation, automated fiber switching becomes a practical control layer for modern rail optical infrastructure.

For operators planning modernization, the key decision is no longer whether to automate the physical layer—but which corridors, cabinets, and OCC workflows deliver the highest risk reduction and fastest operational return first.

© 2018-2026 XENOptics. All Rights Reserved. Terms of Use.